Keywords: Hydraulic Press

+86 188 1880 9064

Request a quote

Home » Application » Assembly Press

| Applicable Industries: | Bushing/bearing insertion, Motor stator core stacking, Transformer stator core stacking, Joining, fastening, riveting, Crimping, clamping, etc | Aftersales Service: | Field installation/maintenance/ repair service, Commissioning and training, Online support, Free spare parts, Video technical support |

| Power Supply: | 380V/220V/415V/480V optional | Certification: | CE/UL/ISO |

| Customizable: | Highly customized to your requirements | Warranty: | 18 months |

| Production Lead-time: | About 30~55 workdays | Payment Term: | T/T |

| Packing: | Wooden package suitable for sea transport | Delivery Term: | EXW, FOB,CFR,CIF,DDU |

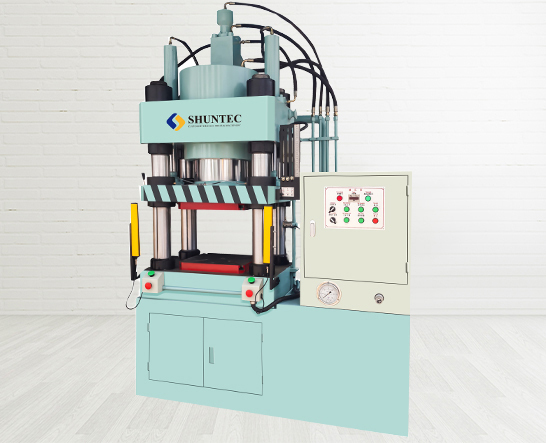

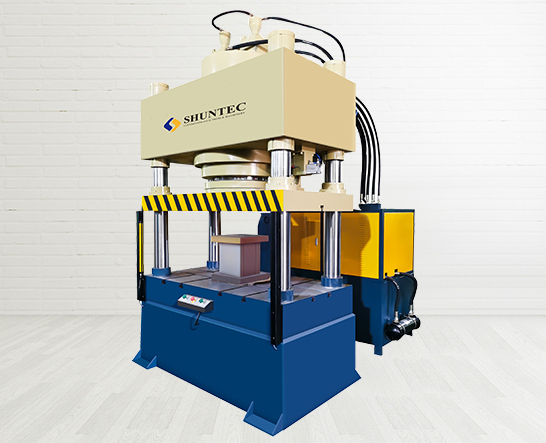

Whether you are looking to add a single assembly press or construct a complete assembly line, Shuntec has extensive experience in engineering solutions for all types of assembly. Our 4-post, C frame, benchtop, and horizontal type assembly presses are most often used for high-force assembling and press-fitting applications, such as bushing/bearing insertion, motor/transformer stator core stacking, joining, fastening, riveting, crimping, clamping, etc.

For some precision assembly applications, the Shuntec integration function of force & position monitoring, multiple assembling modes, and real-time quality evaluation is a must to ensure perfect assembly results. The operation system of our assembling machines is user-friendly, open-architecture programming which allows operators to easily create and store key process parameters while providing data visualization throughout each cycle. We can also fully automate your assembly line with ancillary equipment including conveyors, cameras, RFID scanners, tool storage, and retrieval systems, quick die change options, and robots.

Our hydraulic & servo-electrical assembly press and press fitting machines are both applicable for general and precision assembling jobs. We list hot-sales standard series servo-electrical assembly presses in the right navigation bar. Know more about them by clicking the Machine Technical Parameters.

| Model | 200kgf (0.2 ton) | 500kgf (0.5 ton) | 1000kgf (1 ton) | 2000kgf (2 ton) | 5000kgf (5 ton) | 8000kgf (8 ton) |

| Work Temperature | 0~40℃ | |||||

| Input Power | AC220V SINGLE PHASE (custom-made available) | AC380V 3 PHASE (custom-made available) | ||||

| Power Consumption | 300W | 500W | 800W | 2100W | 4650W | 5650W |

| Human-computer interface | 7-inch or 10-inch touch screen | |||||

| Control Unit | PLC & exclusive control unit | |||||

| Control Mode | 1. Fixed speed, setting position stop 2. Fixed speed, setting load stop 3. Fixed speed, pressing distance stop | |||||

| Drive Mode | Precise AC servo motor | |||||

| USB Interface | USB2.0, download & upload available | |||||

| Die Connector Dia. | Ø8 mm | Ø16 mm | Ø16 mm | Ø20mm | Ø25 mm | Ø30 mm |

| Pressure Output | 200kgf(0.2 ton) | 500kgf (0.5 ton) | 1000kgf (1 ton) | 2000kgf (2 ton) | 5000kgf (5 ton) | 8000kgf (8 ton) |

| Pressure Unit | 0.1kgf | |||||

| Pressure Precision | 0.001 F.S | |||||

| Pressure Repeat Duration | 0.01 F.S | |||||

| Standard Stroke | 50/100 mm | 150/200/250 mm | ||||

| Stroke Unit | 0.001 mm | |||||

| Stroke Repeat Duration | 0.01 mm | |||||

| Fast Forward Speed | 0.1- -160 mm/s | 0.1- -200 mm/s | ||||

| Detect Speed | 0.1- -20 mm/s | 0.1- -30 mm/s | ||||

| Press Speed | 0.1- -35 mm/s | 0.1- -50 mm/s | ||||

| Return Speed | 0.1- -160 mm/s | 0.1- -200 mm/s | ||||

| Dwell Time | 0.1~99.9 second | |||||

• 4-post, C frame, benchtop, and horizontal type frame structure optional

• Indexing units

• Automated loading & unloading system

• Automated assembly line

• Interlocked, hinged guards on 3 sides

• Hydraulic center ejection

• Portable operator console

• Pneumatic safety gates

• Color HMI

• Linear position sensor

• Load cell