Keywords: Hydraulic Press

+86 188 1880 9064

Request a quote

Home » Application » Punching Blanking Press

.

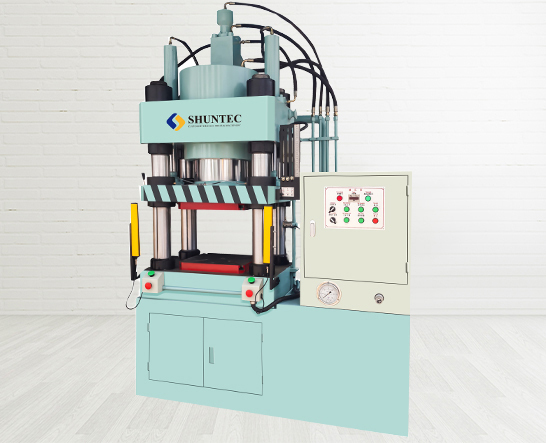

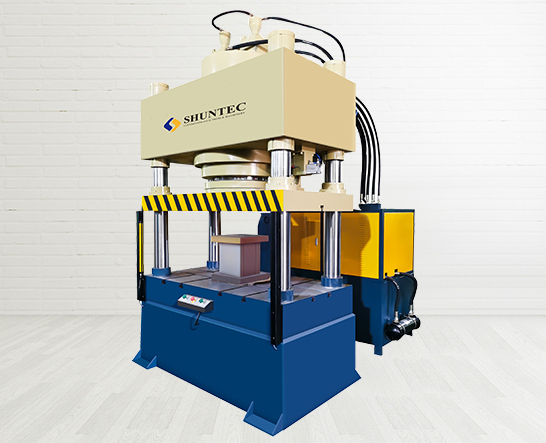

Precision control is the key to achieving the most cost-effective punching and blanking operation, especially for sheet metal automotive parts. To ensure the perfect punching and blanking result, we offer the Shuntec punching press and blanking press the ability of the entire stroke with precision adjustments. At the same time, we provide the best customized hydraulic press solutions with two pressing control modes for the specific requirements: pressure control mode and position control mode.

Additionally, Shuntec punching press & blanking press featured the following characteristics:

• Lightness and stability: the press adopts an overall frame structure to guarantee the lightness and stability of the machine.

• Low power consumption: the servo-hydraulic control system is 30%~60% lower energy consumption compared with the traditional hydraulic control system

• Easy change of molds: change of molds is easily achievable by advanced mold installment technology. A special protection device is available to keep the molds from damage.

• Highly automatic: not only are feeding and discharging automatically controlled units but parts/end products and scraps can also be distinguished automatically as well.

• Convenient feeding system: multiple feeding systems are mounted on both sides of the machine to guarantee quick and convenient feeding.

| Description | Shuntec-A05 100T | Shuntec-A05 150T | Shuntec-A05 200T | Shuntec-A05 300T | Shuntec-A05 500T |

| Structure | 4-post or gib-guide frame | 4-post or gib-guide frame | 4-post or gib-guide frame | 4-post or gib-guide frame | 4-post or gib-guide frame |

| Main Cylinder Force | 1000 KN | 1500 KN | 2000 KN | 3000 KN | 5000 KN |

| Main Cylinder Stroke | 300 mm | 300 mm | 400 mm | 400 mm | 500 mm |

| Max. Daylight | 450 mm | 450 mm | 600 mm | 600 mm | 700 |

| Shut Height | 150 mm | 150 mm | 200 mm | 200 mm | 200 mm |

| Bed Table | 1400*680 mm | 1400*680 mm | 1420*750 mm | 1420*750 mm | 1520*850 mm |

| Closing Speed | 80~110 mm/s | 80~110 mm/s | 100~120 mm/s | 100~120 mm/s | 100~120 mm/s |

| Slow Pressing Speed | 5~8 mm/s | 5~8 mm/s | 2~4 mm/s | 2~4 mm/s | 2~4 mm/s |

| Return Speed | 90~120mm/s | 90~120mm/s | 100~120mm/s | 100~120mm/s | 100~120mm/s |

| Motor | 4 Pole, 7.5KW | 4 Pole, 7.5KW | 4 Pole, 11KW | 4 Pole, 13.5KW | 4 Pole, 15KW |

| Power Supply | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ |

| System Pressure | 20 Mpa | 20 Mpa | 20 Mpa | 20 Mpa | 25 Mpa |

| Machine Approx. Weight | 3 Ton | 4.5 Ton | 5 Ton | 6 Ton | 8 Ton |

• Top-mounted hydraulics

• Anti-tie-down, anti-repeat controls with ring guards

• Safety photoelectric light curtain covering the entire stroke

• Safety interlocked, hinged guards on the 3-sided door

• Air blast valve with timer and air nozzles

• Portable operator console

• Color HMI

• Linear position sensor

• Load sensor

• Bed shuttles

• Automatic safety door systems

• Hydraulic center ejection

• Pneumatic safety rachet

• Automatic tie bar lubrication

• Feeding and discharging automatically controlled units

• Multiple feeding systems

• Automatic mold installment device