Keywords: Hydraulic Press

+86 188 1880 9064

Request a quote

Home » Application » Coining Press

.

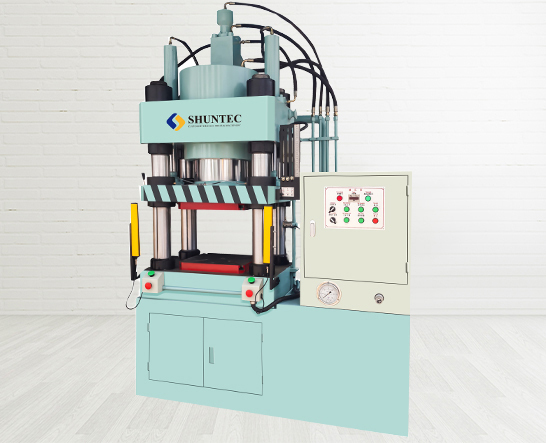

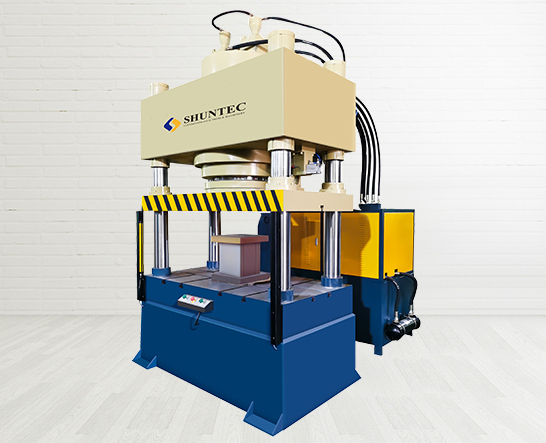

• Much more precise level of ram guidance

• Superior rigidity and bed to platen parallelism

• Gibs are adjustable to ensure accuracy over time

• Multifunctional hydraulic cushion: functions of ejecting/no-ejecting/blank holding selectable

• Modular design, customize to your specifications

Shuntec's coining press can be upgraded with a 4-point or 8-point gib-guided construction to achieve a higher level of machine rigidity and bed-to-ram parallelism. The press is optimally designed to approach the working table quickly and then steadily apply the pressing force to form the parts with well-defined patterns and a clear finish.

The press can be also featured by a fully programmable controls package with the ability to input, modify, and store cycle parameters for rapid recall. As system pressure and ram speed are critical to the customer’s application, both variables are programmable through the machine’s 10” color touchscreen HMI. As an option, an automatic feeding system and collecting device can be added to the press for easy routine operation.

| Description | Shuntec-A08 100T | Shuntec-A08 200T | Shuntec-A08 300T | Shuntec-A08 500T | Shuntec-A08 600T | Shuntec-A08 1000T |

| Structure | 4-post press | 4-post press | 4-post press | 4-post press | 4-post press | 4-post press |

| Main Cylinder Pressure | 21 Mpa | 20 Mpa | 21 Mpa | 25 Mpa | 25 Mpa | 25 Mpa |

| Main Cylinder Force | 1000 KN | 2000 KN | 3000 KN | 5000 KN | 6000 KN | 10000 KN |

| Main Cylinder Stroke | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 250 mm |

| Max. Daylight | 400 mm | 420 mm | 420 mm | 450 mm | 450 mm | 450 mm |

| Bed Table | 430*450 mm | 530*530 mm | 590*600 mm | 740*740 mm | 810*810 mm | 920*920 mm |

| Ejection Cylinder | available | available | available | available | available | available |

| Closing Speed | 115 mm/s | 115 mm/s | 115 mm/s | 100 mm/s | 100 mm/s | 100 mm/s |

| Pressing Speed | 10~25 mm/s | 12~23 mm/s | 12~30 mm/s | 10~22 mm/s | 10~30 mm/s | 10~28 mm/s |

| Return Speed | 100 mm/s | 100 mm/s | 100 mm/s | 120 mm/s | 120 mm/s | 120 mm/s |

| Motor | 4 Pole, 5.5KW | 4 Pole, 7.5KW | 4 Pole, 7.5KW | 4 Pole, 11KW | 4 Pole, 15KW | 4 Pole, 18.5KW |

| Power Supply | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ |

| Overall Dimensions | 1310*1190*1650 mm | 1450*1190*1660 mm | 1530*1190*1740 mm | 1885*1440*2130 mm | 2030*1440*2420 mm | 2330*1490*2660 mm |

| Approx. Weight | 2.5 T | 3.6 T | 4.5 T | 9.2 T | 12 T | 17.2 T |

• Top-mounted hydraulics

• Anti-tie-down, anti-repeat controls with ring guards

• Safety photoelectric light curtain covering the entire stroke

• Safety interlocked, hinged guards on the 3-sided door

• Air blast valve with timer and air nozzles

• Portable operator console

• Color HMI

• Linear position sensor

• Load sensor

• Bed shuttles

• Automatic safety door systems

• Hydraulic center ejection

• Pneumatic safety rachet

• Automatic tie bar lubrication

• Feeding and discharging automatically controlled units

• Multiple feeding systems

• Automatic mold installment device