Keywords: Hydraulic Press

+86 188 1880 9064

Request a quote

Home » Application » Deep Drawing Press

| Applicable Industries: | For metal deep drawing forming, widely used in appliance industry, automotive industry, aerospace and medical industries, etc | Aftersales Service: | Field installation/maintenance/ repair service, Commissioning and training, Online support, Free spare parts, Video technical support |

| Power Supply: | 380V/220V/415V/480V optional | Certification: | CE/UL/ISO |

| Customizable: | Highly customized to your requirements | Warranty: | 18 months |

| Production Lead-time: | About 30~55 workdays | Payment Term: | T/T |

| Packing: | Wooden package suitable for sea transport | Delivery Term: | EXW, FOB,CFR,CIF,DDU |

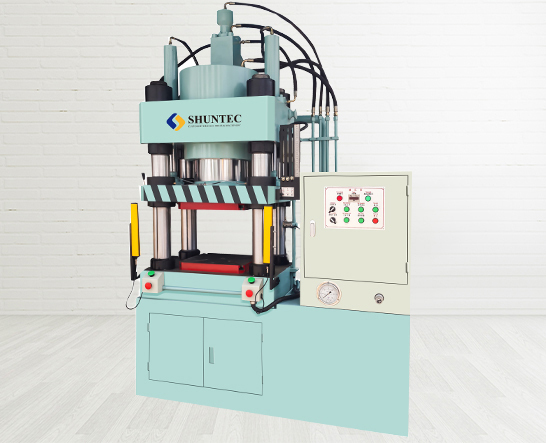

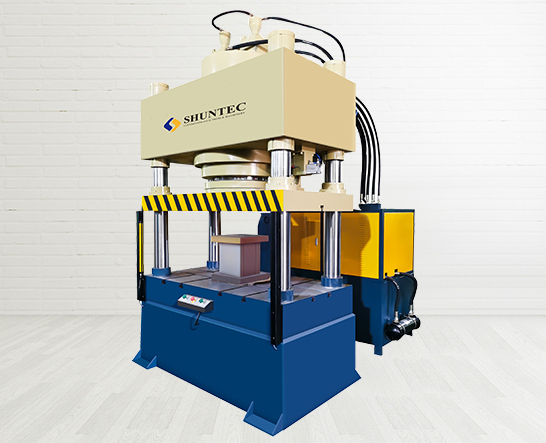

Shuntec's standard deep drawing press ranges in tonnage from 45 to 1000 tons and features a compact and intuitive design. Heavy-duty 4-post and stress-relieved frame bodies are extremely rigid and have minimum deflection to provide perfect rigidity and durability. Well-forged and precise-polished heavy-duty cylinders remain highly reliable when machines run in high load conditions.

During the most common draw forming applications, a punch is mounted on the press bed, and the blank material sits on the draw ring supported by the bed cushion. When the upper tool contacts the blank, the cushion retracts downward, forming the material over the stationary punch. Unique to our deep drawing hydraulic press is that the pressure output of the machine is dynamically changing due to the pressure proportioning function of the main cylinder and lower blank hold cylinder. Our deep drawing press allows for tonnage adjustments throughout the entire draw process, giving the operator complete control over material flow to eliminate wrinkling and tearing. The main cylinder pressure proportioning can reduce the loss of force during the drawing process so. The lower cylinder pressure proportioning can reduce the force of blank holding along with the change of drawing height and blank holding size. This optional function allows our customers to achieve maximum productivity and minimum rejection rate.

Additionally, Shuntec can work directly with your tooling suppliers from the beginning of your deep drawing project, and ensure that the press is optimized and workable with your tooling. Check the right navigation bar for details of standard deep drawing presses.

| Description | Shuntec-A02 65T | Shuntec-A02 100T | Shuntec-A02 150T | Shuntec-A02 200T | Shuntec-A02 350T | Shuntec-A02 500T |

| Structure | 4-post press | 4-post press | 4-post press | 4-post press | 4-post press | 4-post press |

| Main Cylinder Pressure | 20 Mpa | 20 Mpa | 20 Mpa | 20 Mpa | 20 Mpa | 20 Mpa |

| Main Cylinder Force | 400 KN | 600 KN | 1000 KN | 1500 KN | 2500 KN | 3500 KN |

| Main Cylinder Stroke | 450 mm | 450 mm | 500 mm | 550 mm | 600 mm | 650 mm |

| Blank Holder Cylinder Pressure | 20 Mpa | 20 Mpa | 20 Mpa | 20 Mpa | 25 Mpa | 25Mpa |

| Blank Holder Cylinder Force | 250 KN | 400 KN | 500 KN | 500 KN | 1000 KN | 1500 KN |

| Blank Holder Cylinder Stroke | 200 mm | 250 mm | 250 mm | 300 mm | 300 mm | 300 mm |

| Ejection Cylinder Force | 20 KN | 20 KN | 20 KN | 25 KN | 40 KN | 50 KN |

| Ejection Cylinder Stroke | 160 mm | 180 mm | 200 mm | 210 mm | 220 mm | 250 mm |

| Max. Daylight | 750 mm | 850 mm | 900 mm | 1000 mm | 1100 mm | 1150 mm |

| Shut Height | 300 mm | 400 mm | 400 mm | 450 mm | 500 mm | 500 mm |

| Bed Table | 550*600 mm | 600*700 mm | 650*750 mm | 700*800 mm | 850*950 mm | 1000*1100 mm |

| Closing Speed | 190 mm/s | 210 mm/s | 175 mm/s | 130 mm/s | 135 mm/s | 190 mm/s |

| Slow Pressing Speed | 10~25 mm/s | 12~23 mm/s | 12~30 mm/s | 10~22 mm/s | 10~30 mm/s | 10~28 mm/s |

| Return Speed | 220 mm/s | 120 mm/s | 155 mm/s | 150 mm/s | 235 mm/s | 190 mm/s |

| Blank Holder Upward Speed | 75 mm/s | 75 mm/s | 65 mm/s | 85 mm/s | 90 mm/s | 80 mm/s |

| Ejection Speed | 60 mm/s | 60 mm/s | 60 mm/s | 60 mm/s | 60 mm/s | 60 mm/s |

| Motor | 4 Pole, 7.5KW | 4 Pole, 11KW | 4 Pole, 15KW | 4 Pole, 30KW | 4 Pole, 30KW | 4 Pole, 45KW |

| Power Supply | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ |

| Overall Dimensions | 1555*1090*2735 mm | 1710*1370*3200 mm | 1840*1430*3375 mm | 1900*1480*3645 mm | 2290*2055*4100 mm | 2575*1950*4395 mm |

| Machine Approx. Weight | 3 Ton | 4.5 Ton | 5 Ton | 8 Ton | 10 Ton | 15 ton |

• Anti-tie-down, anti-repeat controls with ring guards

• Interlocked, hinged guards on 3 sides

• Hydraulic center ejection

• Portable operator console

• Safety ratchet bar

• Pneumatic safety gates

• Color HMI

• Linear position sensor

• Load cell

• Automatic tie bar lubrication

• Top-mounted hydraulics