Keywords: Hydraulic Press

+86 188 1880 9064

Request a quote

Home » Application » Trim Press

| Applicable Industries: | Ancillary processing machine for metal deep drawing parts, metal diecasting parts, metal stamping parts. Widely used in Automotive industry | Aftersales Service: | Field installation/maintenance/ repair service, Commissioning and training, Online support, Free spare parts, Video technical support |

| Power Supply: | 380V/220V/415V/480V optional | Certification: | CE/UL/ISO |

| Customizable: | Highly customized to your requirements | Warranty: | 18 months |

| Production Lead-time: | About 30~55 workdays | Payment Term: | T/T |

| Packing: | Wooden package suitable for sea transport | Delivery Term: | EXW, FOB,CFR,CIF,DDU |

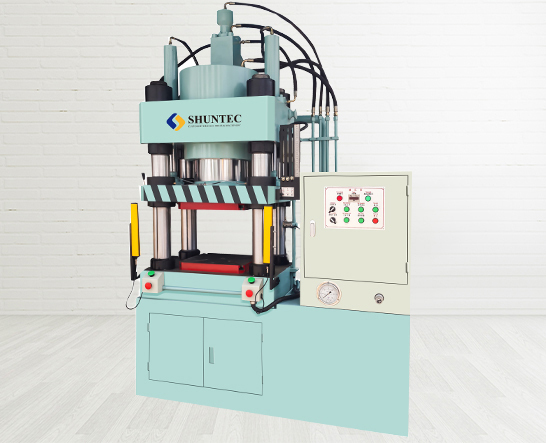

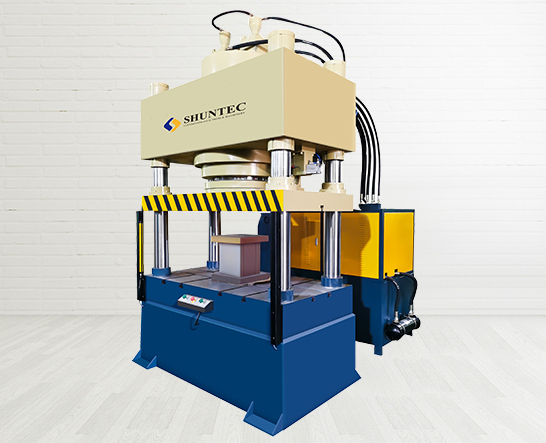

Our trimming presses are heavy-duty 4-post hydraulic presses. All trimming machines in Shuntec are guided by quality graphite-impregnated self-lubricated bronze bushings and four solid, chrome-plated posts. The long bearing length provides perfect stability and effective resistance to off-center loading.

One of the main applications is to remove the burr of die casting parts. As trim presses are commonly working under high temperature and excessive conditions when removing the flash of the die casting parts, all hydraulic and electric units which Shuntec used are of world-wide famous brand with tough quality, to ensure years of dependable use and maintenance-free.

Since trimming is typically a secondary process within the whole production line of die casting, our trimming presses are open-designed and brings the ability to integrate into any other production cells such as waste unloading unit or robots to maximize your process efficiency.

We list hot-sales standard 4-post trim presses in the right navigation bar. Know more about them by clicking the Machine Technical Parameters.

| Description | Shuntec-A03 30T | Shuntec-A03 50T | Shuntec-A03 80T | Shuntec-A03 100T | Shuntec-A03 150T | Shuntec-A03 200T |

| Nominal Force | 300 KN | 500 KN | 800 KN | 1000 KN | 1500 KN | 2000 KN |

| Structure | 4-post press | 4-post press | 4-post press | 4-post press | 4-post press | 4-post press |

| Cylinder Stroke | 300 mm | 300 mm | 500 mm | 800 mm | 900 mm | 1000 mm |

| Max. Daylight | 500 mm | 500 mm | 800 mm | 1100 mm | 1200 mm | 13000 |

| Shut Height | 200 mm | 200 mm | 300 mm | 300 mm | 300 mm | 300 mm |

| Bed Table | 550*400 mm | 600*500 mm | 800*650 mm | 1000*860 mm | 1100*960 mm | 1200*1060 mm |

| Closing Speed | 170~180 mm/s | 140~150 mm/s | 140~150 mm/s | 170~180 mm/s | 170~180 mm/s | 170~180 mm/s |

| Slow Pressing Speed | 5~12 mm/s | 5~12 mm/s | 5~12 mm/s | 5~12 mm/s | 5~12 mm/s | 5~12 mm/s |

| Return Speed | 130~150mm/s | 120~130 mm/s | 120~130 mm/s | 120~130 mm/s | 120~130 mm/s | 120~130 mm/s |

| Motor | 4 Pole, 3KW | 4 Pole, 5.5KW | 4 Pole, 5.5KW | 4 Pole, 7.5KW | 4 Pole, 11KW | 4 Pole, 15KW |

| Power Supply | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ | 3Phase, 220/380/415/480VAC, 50/60HZ |

| System Pressure | 20 Mpa | 20 Mpa | 20 Mpa | 20 Mpa | 20 Mpa | 25 Mpa |

| Machine Approx. Weight | 3 Ton | 4.5 Ton | 5 Ton | 6 Ton | 7.5 Ton | 8 Ton |

• Shuttles and belt systems for loading and unloading

• Conveyor systems and chutes for scrap removal

• Automate system with robots

• Anti-tie-down, anti-repeat controls with ring

• Interlocked, hinged guards on 3 sides

• Hydraulic center ejection

• Air blast valve with timer and air nozzles

• Removable base

• Portable operator console

• Safety ratchet bar

• Pneumatic safety gates

• Color HMI

• Linear position sensor

• Load cell

• Automatic tie bar lubrication

• Top-mounted hydraulics